- Products and Services by Category

- Aircraft spares / MRO

- Aircraft test equipment

- Bearings, slip rings

- Brakes

- Connection accesories, connection systems

- Consumables & chemicals

- Electric cables and harnesses

- Fans

- Filters and filtration systems

- Fixing parts

- Fixings products, elastomer seals

- Flexible hoses, seals and circuits

- Fuel and lubricants

- Ground handling and assistance equipment

- Hydraulic components, systems and tests

- In-flight tests and assistance

- Other

- Piping

- Sensors, pressure controllers, etc.

- Spare parts

- Springs

- Test equipment for airflow measurement

- Tools and tooling

- Aircraft interiors

- Airport equipment

- Civil aircrafts

- Cockpit, engine and airframe

- Defence & weapons systems

- General aviation & leisure

- Rotorcrafts / Helicopters

- Satellite, space launchers & equipment

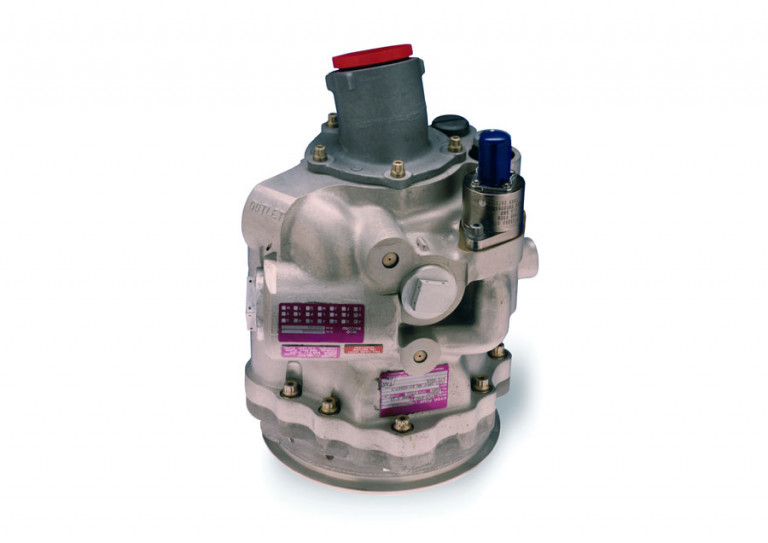

Hydraulic engine-driven pump

Hydraulic engine-driven pump

Eaton

1000 Eaton Boulevard44122 - Cleveland, OH

États-Unis

Eaton is a power management company with 2015 sales of $20.9 billion. Eaton provides energy-efficient solutions that help our customers effect...

Hydraulic engine-driven pump

Engine-Driven Pump for Boeing's B737-600/700/800/900, Model PV3-240-18

Eaton's Vickers® part number 849589 (model PV3-240-18) main Engine-Driven Pump (EDP) was specifically designed to meet the requirements of the Boeing 737-600/700/800/900 aircraft. This state-of-the-art engine-driven pump offers superior performance, higher horsepower to weight ratio, and lower operating costs. It delivers 37.5 gpm (142 L/min) at 3750 rpm and a 2850 psi (19651 kPa). The design of the pump is drawn from Eaton's Vickers product line of highly reliable 2.40 cu/in displacement pumps and has significant reduction in weight and volume. Model PV3-240-18 incorporates the field proven, reliable model PV3-240-2 and -10 pump rotating components together with improved reliability and weight reduction technology developed from the B777 engine-driven pump program. Many piece parts from the current model PV3-240 production models are incorporated in the new unit, which reduces spare parts inventory requirements.

DESIGN FEATURES

Model PV3-240-18 incorporates numerous design features to improve the reliability and maintainability of the unit.

Increased Fatigue Strength

All castings are designed for improved fatigue characteristics through specific structural design based on finite element analysis and use of improved casting materials.

Proven Shaft and Yoke Bearings

All bearings used in model PV3-240-18 EDP carry the same part numbers as model PV3-240 series. This will reduce spare parts inventory.

Hollow Drive Shaft

The drive shaft is hollow for weight reduction. The internal surface created by the weight reduction is coated for corrosion control.

Improved Cylinder Bloc Material

The cylinder block is machined from ductile iron to minimize wear in the drive spline and piston bores. Bronze plating on the cylinder block surface provides a durable bearing surface for wear against the tool steel valve plate.