- Products and Services by Category

- Aircraft spares / MRO

- Aircraft test equipment

- Bearings, slip rings

- Brakes

- Connection accesories, connection systems

- Consumables & chemicals

- Electric cables and harnesses

- Fans

- Filters and filtration systems

- Fixing parts

- Fixings products, elastomer seals

- Flexible hoses, seals and circuits

- Fuel and lubricants

- Ground handling and assistance equipment

- Hydraulic components, systems and tests

- In-flight tests and assistance

- Other

- Piping

- Sensors, pressure controllers, etc.

- Spare parts

- Springs

- Test equipment for airflow measurement

- Tools and tooling

- Aircraft interiors

- Airport equipment

- Civil aircrafts

- Cockpit, engine and airframe

- Defence & weapons systems

- General aviation & leisure

- Rotorcrafts / Helicopters

- Satellite, space launchers & equipment

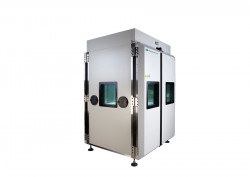

Automated pitot static tester Model 6200

Automated pitot static tester Model 6200

Laversab

505 Gillingham Lane77478 - Sugar Land, TX

États-Unis

Founded in 1982, Laversab began as a key supplier to governments worldwide for high accuracy, pressure calibration instrumentation. As an audi...

Automated pitot static tester Model 6200

Features

WiFi-enabled

Automated operation (at an Affordable price)

Simply enter the target set-points for altitude and airspeed and the unit automatically achieves the targets, ramping at the programmed rates. Control at the set-point is stable within ± 1 foot and ± 0.1 knot. The tester's low price makes it very affordable

Calibration period: 1 year

Programmable limits

User-programmable limits for altitude, airspeed, Mach, VSI and airspeed-rate provide protection to the aircraft.

Negative-airspeed protection

An internal differential-pressure relief valve provides protection against negative airspeed.

Internal Battery (Optional)

The internal battery allows for 8 hours of continuous operation. Re-charge time is only 8 hours.

Low-temperature operation (optional)

With optional internal heaters, the unit can be operated down to -40°C

“Jog” and “Hold” features

Set-points can be “jogged” up or down in small increments. Ramping to a set-point can be put on “hold” and controlled at the current measured value.

“Ground” feature

Brings Pitot and Static outputs to ambient “ground” pressure after completing a test. Ambient pressure is constantly monitored.

“Profiles” feature

A profile of set-points can be downloaded from a PC, allowing the user to step through the set-points using a single key. Each profile can have up to 50 set-points and 15 profiles can be stored in the unit.

Leak checks

Pitot and Static leak-checks can be performed either independently or simultaneously. Three leak-timers can be programmed to perform timed leaks between 1 to 20 minutes. The display of “instant” leak rates provides immediate feedback to the user.

Pressure & Vacuum source

Built-in diaphragm pumps provide the pressure and vacuum source for the unit.

Remote unit

The Remote unit is the operator interface for the tester. It features a sunlight-readable 5.8” color display, a back-lit keypad and a touch-screen (which can be disabled). All operations are performed from a single screen which displays all pertinent parameters.

Manual Vent Valves

On loss of power, the unit maintains pressure (except for leaks). The unit can be manually vented to “Ground” at a controlled rate using precision metering valves.

Applications

- Leak-checks and accuracy-checks on all non-RVSM aircraft, helicopters or UAVs.

- Leak-checks and limited accuracy-checks on RVSM aircraft

- Ideal for line-maintenance by commercial airlines